Written by: Krizia Joy Rivera

Entering the world of 3D printing can be both exciting and overwhelming. As a beginner, you’re faced with a steep learning curve, from understanding the intricacies of your printer to mastering the software and materials. Looking back, there are several key tips and tricks I wish I knew when I started. In this article, I'll share those insights to help you avoid common pitfalls and fast-track your journey to 3D printing success.

Understanding the Basics of 3D Printing

Before diving into the advanced techniques, it’s crucial to have a solid grasp of the basics. 3D printing, also known as additive manufacturing, involves creating three-dimensional objects from digital files by adding material layer by layer. The process starts with a 3D model, usually created in CAD (Computer-Aided Design) software, which is then sliced into layers that the printer can follow to build the object.

Choosing the Right 3D Printer

Not all 3D printers are created equal. As a beginner, it's essential to select a printer that matches your skill level and project goals. FDM (Fused Deposition Modeling) printers are generally more beginner-friendly due to their affordability and ease of use.

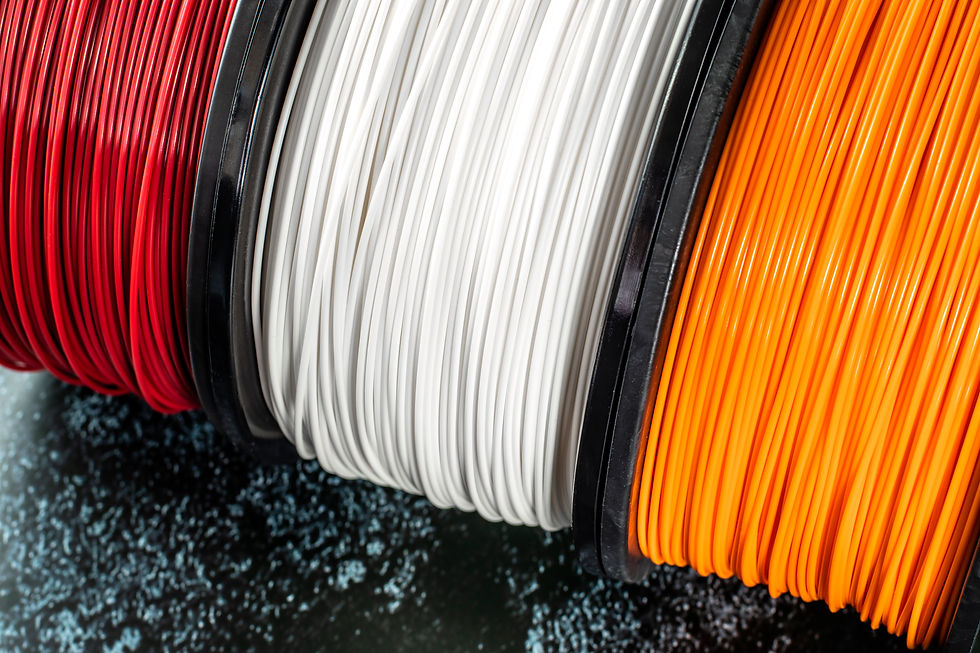

Selecting the Right Materials

The type of material you use can significantly impact the quality of your prints. PLA (Polylactic Acid) is a popular choice for beginners due to its ease of use, low printing temperature, and biodegradability. ABS (Acrylonitrile Butadiene Styrene) is more durable but requires higher temperatures and can emit fumes, necessitating proper ventilation.

Other materials like PETG (Polyethylene Terephthalate Glycol) and TPU (Thermoplastic Polyurethane) offer different properties like flexibility and strength but come with their own challenges. It's essential to choose the material that best suits your project's needs while considering factors like print temperature, bed adhesion, and post-processing requirements.

Mastering the Slicing Software

Slicing software translates your 3D model into instructions your printer can follow. Programs like Cura, PrusaSlicer, and Simplify3D are popular among hobbyists. Understanding how to optimize settings like layer height, infill density, and print speed can drastically improve the quality of your prints.

Layer Height and Resolution

Layer height determines the level of detail in your print. A smaller layer height (e.g., 0.1mm) produces finer details but takes longer to print, while a larger layer height (e.g., 0.3mm) prints faster but with less detail. Finding the right balance based on your project’s needs is key.

Infill Patterns and Density

Infill refers to the internal structure of your 3D print. A higher infill density results in a stronger object but uses more material and increases print time. Beginners should start with basic patterns like grid or honeycomb at around 20% density, which provides a good balance between strength and material usage.

Preparing Your Printer

Proper printer preparation is essential to avoid failed prints. This includes leveling the bed, ensuring proper nozzle and bed temperature settings, and maintaining your printer regularly.

Bed Leveling

A well-leveled bed ensures that the first layer of your print adheres properly, which is crucial for the success of the entire print. Many beginners struggle with this step, but tools like auto bed leveling or manual leveling guides can simplify the process. Regular checks and adjustments can prevent frustrating failures.

Bed Adhesion Techniques

Getting your print to stick to the bed can be challenging. Common solutions include using a heated bed, applying adhesive like glue sticks or hairspray, or using specific surfaces like PEI sheets or BuildTak. Ensuring a good first layer is critical to preventing warping and other issues.

Troubleshooting Common Issues

Every 3D printing enthusiast faces issues at some point. Learning to troubleshoot common problems can save you time and frustration.

Warping and Cracking

Warping occurs when the edges of your print lift off the bed, usually due to uneven cooling. Solutions include using a heated bed, adding a brim or raft to your print, or enclosing your printer to maintain a consistent temperature. Cracking, especially in taller prints, often happens with materials like ABS and can be mitigated by adjusting the print temperature or slowing down the print speed.

Stringing and Blobbing

Stringing occurs when thin strands of plastic appear between different parts of your print, often due to incorrect retraction settings. Blobbing, or excess material buildup, usually happens when the print speed is too slow or the nozzle temperature is too high. Fine-tuning retraction settings and adjusting temperatures can help resolve these issues.

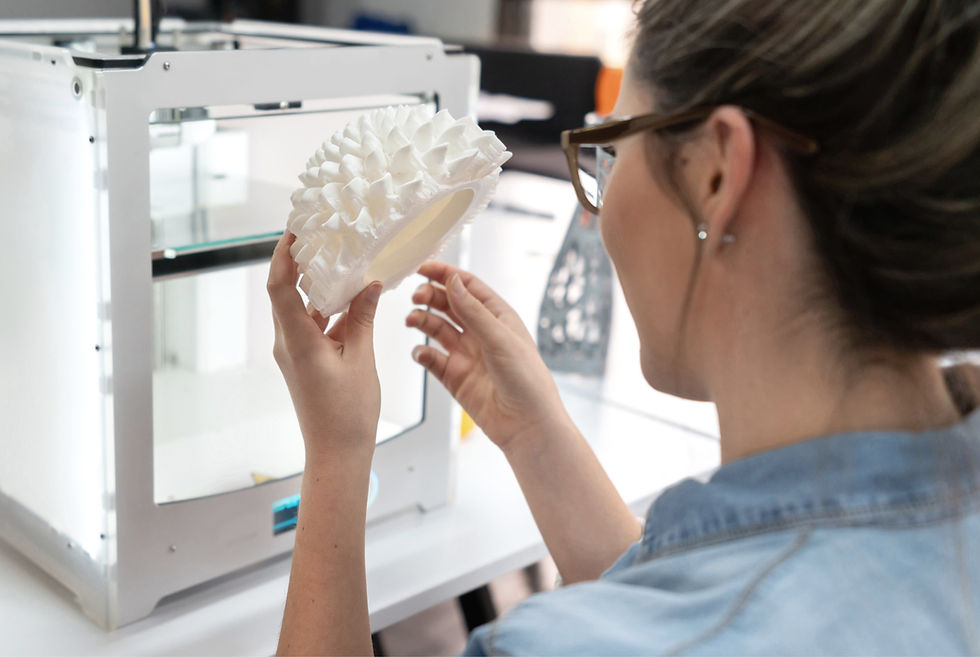

Enhancing Your 3D Printing Skills

As you become more comfortable with your 3D printer, you’ll want to explore advanced techniques to improve your prints and expand your capabilities.

Post-Processing Techniques

Post-processing can take your prints from good to great. Sanding, painting, and applying chemical treatments like acetone vapor smoothing (for ABS) can significantly improve the finish of your prints. Learning how to properly clean up and polish your prints is a valuable skill that enhances the overall quality of your work.

Experimenting with Advanced Materials

Once you've mastered basic materials like PLA, you can start experimenting with more advanced filaments like wood-filled PLA, metal-filled PLA, or even carbon fiber-infused materials. These materials can offer unique properties and finishes but often require more precise printer settings and conditions.

Designing Your Own Models

Creating your own 3D models opens up endless possibilities for customization and creativity. Beginners can start with free CAD software like Tinkercad or Fusion 360. Learning to design with 3D printing in mind, considering factors like overhangs, supports, and tolerances, will help you create more successful prints.

Building a Support Network

Joining a community of fellow 3D printing enthusiasts can provide invaluable support and resources. Online forums, social media groups, and local maker spaces are great places to share tips, ask questions, and learn from others' experiences.

Learning from Others' Mistakes

One of the best ways to improve your 3D printing skills is by learning from others' mistakes. Many enthusiasts share their failures and the lessons learned online, providing insights that can save you time and frustration. Watching tutorials, reading blogs, and participating in discussions can help you avoid common pitfalls and discover new techniques.

Staying Up-to-Date with Trends

The 3D printing industry is constantly evolving, with new technologies, materials, and techniques emerging regularly. Staying informed about the latest trends can help you keep your skills sharp and ensure you're using the best tools available.

FAQs

What’s the best 3D printer for beginners?

The best 3D printer for beginners is typically an FDM printer due to its ease of use and affordability. Popular models include the Creality Ender 3 and Prusa Mini.

How do I prevent my 3D prints from warping?

Warping can be prevented by using a heated bed, ensuring proper bed adhesion with adhesives, and controlling the ambient temperature around the printer.

Which slicing software should I use as a beginner?

Cura is a popular, user-friendly slicing software that is great for beginners. It offers a wide range of presets and settings to help you optimize your prints.

What materials should I start with in 3D printing?

PLA is the best material for beginners due to its ease of use, low printing temperature, and wide availability. As you gain experience, you can experiment with other materials like ABS or PETG.

How do I improve the surface finish of my 3D prints?

Improving the surface finish can be achieved through post-processing techniques like sanding, painting, or using chemical treatments like acetone vapor for ABS prints.

What should I do if my prints are not sticking to the bed?

If your prints aren’t sticking, try re-leveling the bed, increasing the bed temperature, or applying an adhesive like a glue stick or hairspray to the print bed.

3D Printing Tips and Tricks

3D printing is a rewarding hobby that combines creativity with technical skills. By understanding the basics, mastering your tools, and learning from both your own and others' experiences, you can avoid common pitfalls and rapidly improve your skills. The tips and tricks shared here are ones I wish I had known earlier, and they will undoubtedly help you on your 3D printing journey. Remember, patience and practice are key, and every print, whether a success or a failure, is a step towards becoming a more skilled 3D printing enthusiast.

Comments